Test Stand for Rocket Combustion Chamber

September 2021

JHU AstroJays Rocketry Team

Objectives:

Skills Applied:

Comments:

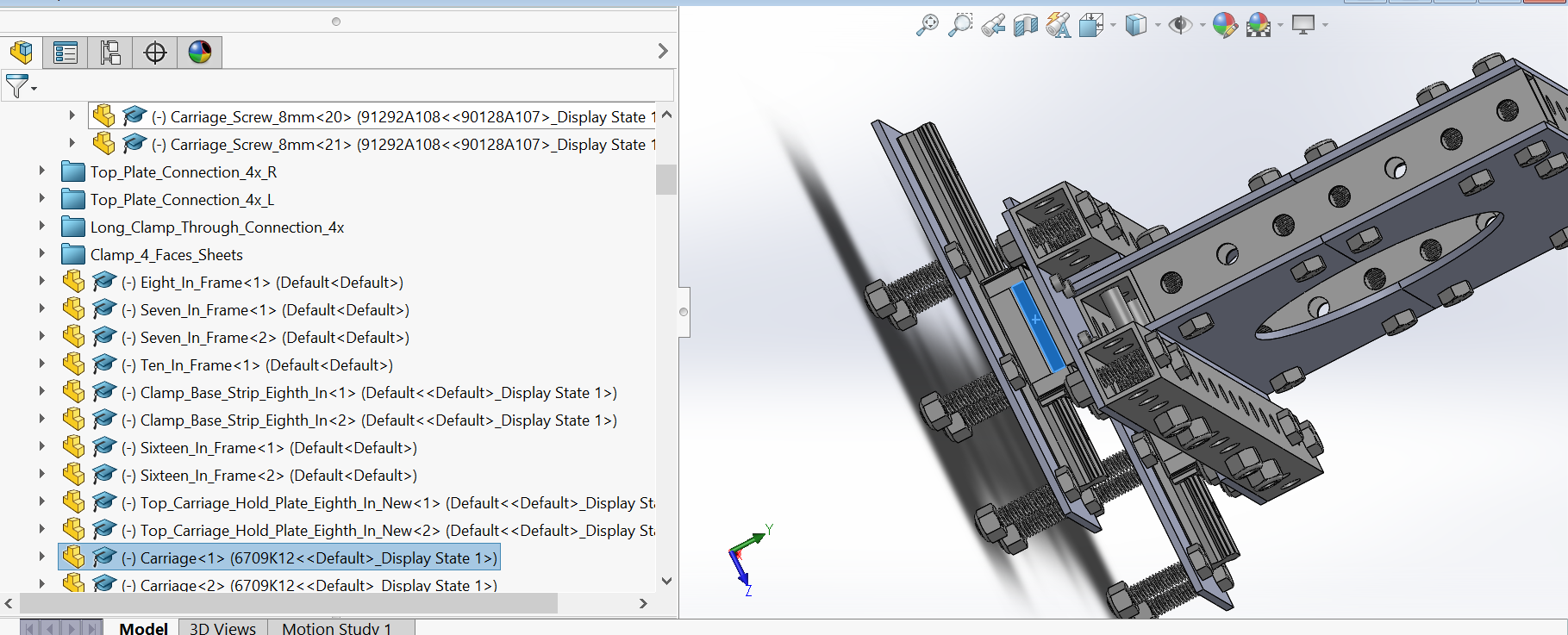

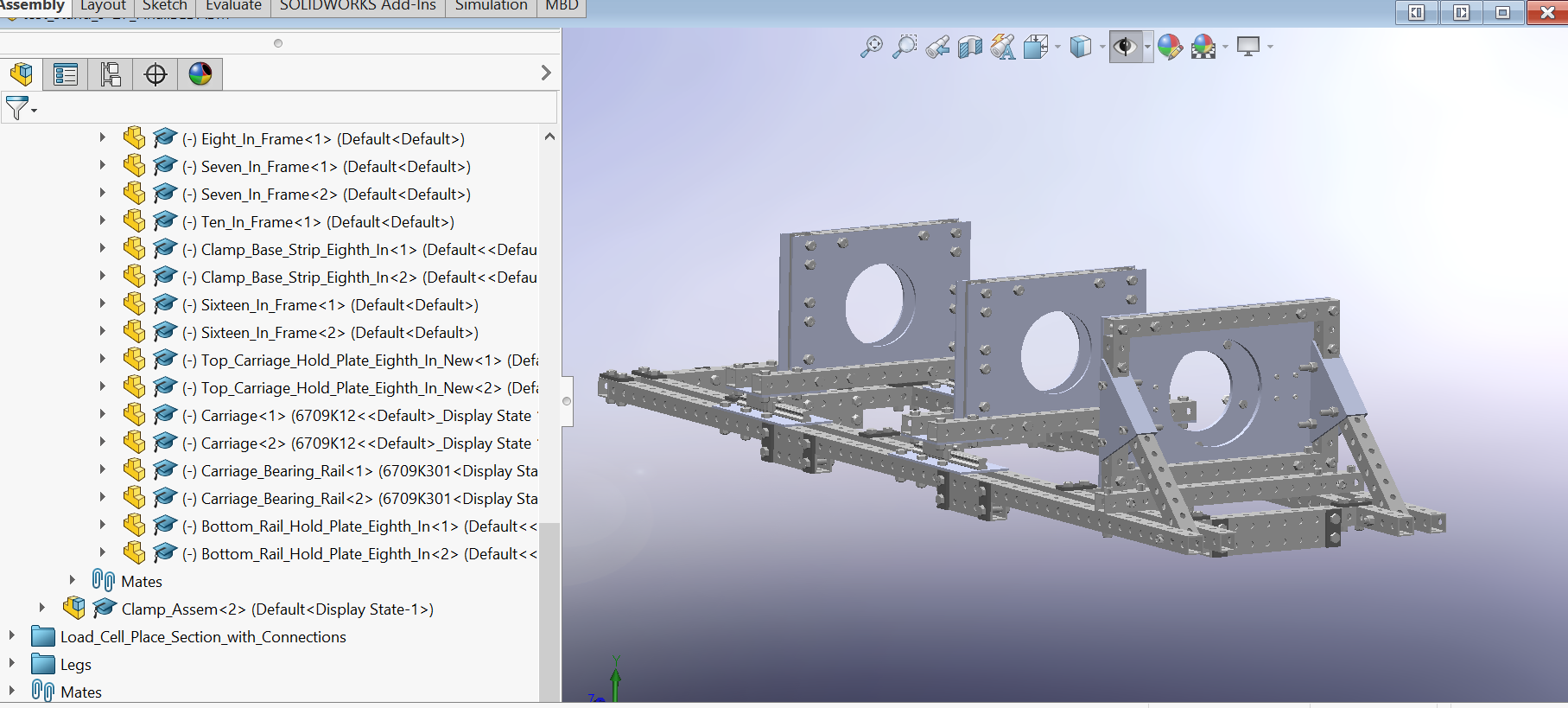

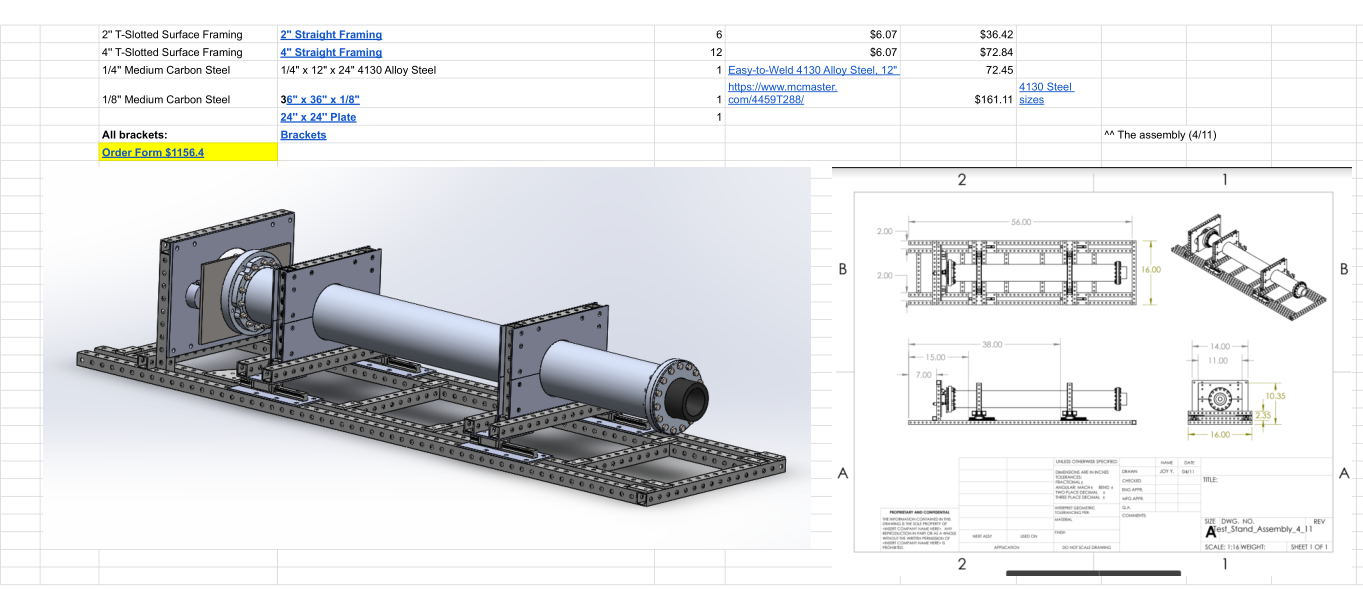

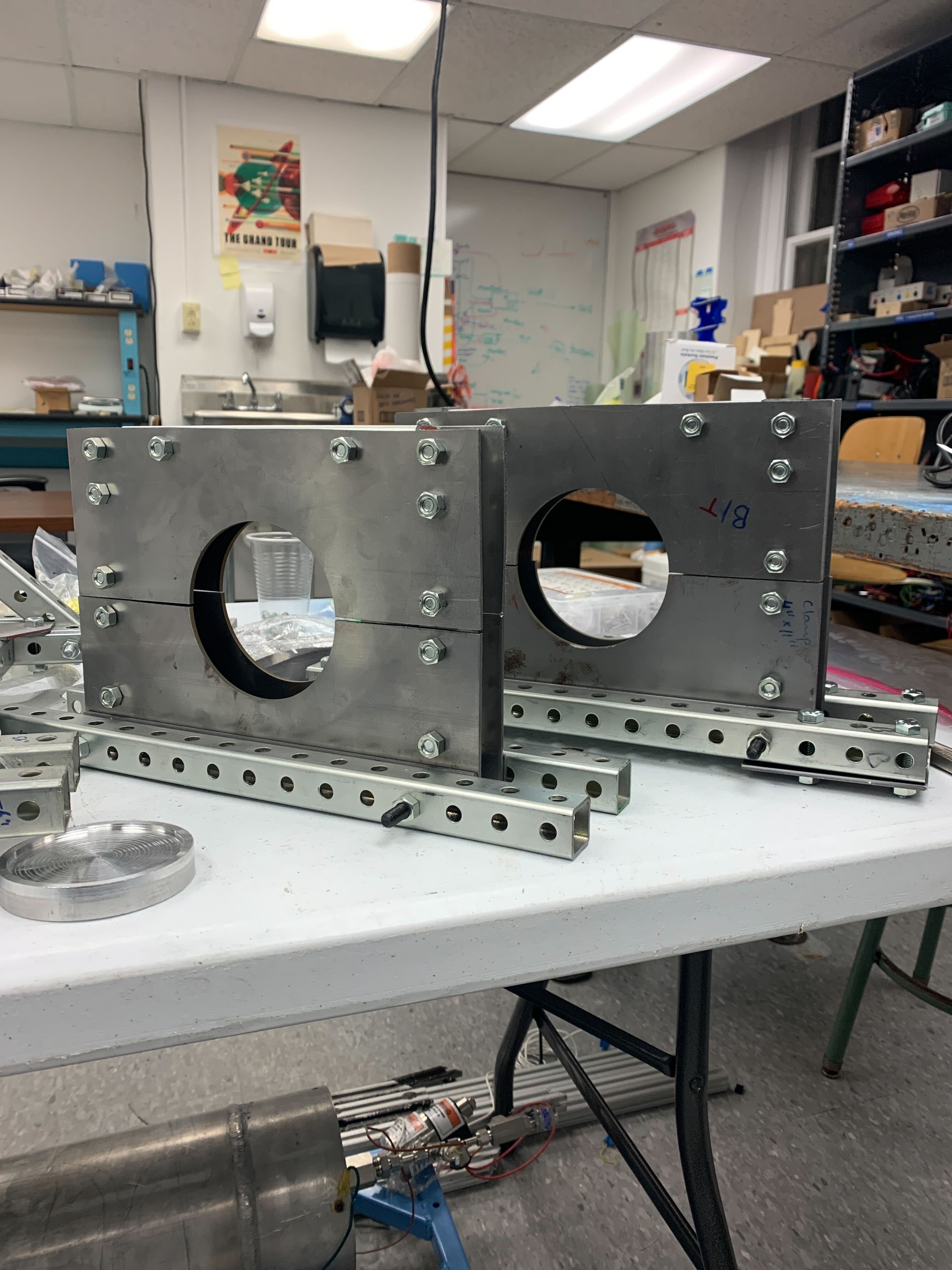

The clamp assemblies (Image from Rishi Bachani).